To store your ice cream machine during the off-season, start by thoroughly cleaning and drying all parts to prevent mold and rust. Disassemble removable components and inspect for wear or damage, lubricating moving parts if needed. Store everything in a clean, dry, and well-ventilated space away from extreme temperatures. Protect your machine with covers to keep dust and moisture out. If you follow these steps, you’ll make sure your machine stays in top shape for next season. Keep going to learn more tips.

Key Takeaways

- Unplug the machine, remove leftover ingredients, and wash all removable parts with warm water and mild detergent.

- Dry all components thoroughly using towels or air drying to prevent mold and rust.

- Inspect for damage or wear, repairing or replacing parts as needed before storage.

- Store disassembled parts in labeled, airtight containers in a dry, dust-free environment.

- Cover the main unit with a breathable cover or plastic wrap and store in a cool, stable, humidity-controlled area.

Empty and Clean the Machine Thoroughly

Before storing your ice cream machine for the off-season, it is vital to empty and clean it thoroughly. Proper seasonal maintenance prevents mold, bacteria, and unpleasant odors from developing while it’s stored. Start by unplugging the machine and removing any leftover ice cream or ingredients. Use warm water and mild detergent to wash all removable parts, ensuring you eliminate any residue. Wipe down the interior and exterior surfaces with a damp cloth to remove dust and dirt. Rinse and dry all components completely to prevent rust and mold growth. These storage tips will keep your machine in top condition and ready for use when the season returns. Additionally, inspecting the machine for any toilet maintenance and repairs issues before storage can help address potential problems early. Incorporating a proper cleaning routine can extend the lifespan of your appliance and ensure it functions correctly when needed, especially considering how art and material significance influence maintenance practices across different tools and devices. Regular maintenance also contributes to water conservation, which is crucial for eco-friendly operation. Moreover, implementing a preventative maintenance plan can help catch minor issues before they become major repairs, saving time and money in the long run.

Disassemble and Dry All Parts

You should remove all components from the machine to prevent damage during storage. Make sure each part is thoroughly dried to avoid mold and corrosion. Taking these steps will help keep your ice cream maker in top shape for next season. Additionally, storing the parts in a dry environment will further protect against moisture damage and ensure longevity. Proper maintenance, similar to ECU tuning for vehicles, helps maintain optimal performance and extends the lifespan of your equipment. Regular inspections and preventative care are essential to identify potential issues early and keep your appliance functioning properly over time. Moreover, incorporating AI-driven diagnostics can assist in early detection of problems, further safeguarding your device. Remember that fatherly guidance and careful care are essential to preserve your appliance’s quality over time.

Remove All Components

Disassembling your ice cream machine is an essential step to guarantee it stays in good condition during the off-season. Carefully remove all components, such as the dasher, mixing bowl, and lid, ensuring they are compatible with your machine’s model. Check component compatibility to avoid damage during reassembly. Once all parts are separated, place them in appropriate storage container options—preferably labeled and sealed—to prevent dust and moisture from settling. This process helps prevent mold or corrosion and makes cleaning easier later. Be thorough in removing any residual product or debris from each part. Disassembly not only protects your machine but also prepares it for a safe, compact storage period, ensuring it remains in prime condition until you’re ready to use it again. Additionally, proper storage techniques can help prevent damage caused by environmental factors during the off-season. Using moisture control methods in your storage area can further safeguard your equipment from humidity damage. To further ensure longevity, consider protective covers that shield your machine from dust and pests when not in use. Incorporating high-pressure cleaning before storage can also remove stubborn residues and enhance maintenance. Remember, regular maintenance is crucial for extending the lifespan of your appliance and ensuring optimal performance when you resume use.

Ensure Complete Drying

Once all components are disassembled, it’s essential to thoroughly dry each part to prevent mold, rust, and corrosion. Proper drying is a key cleaning tip for long-term storage. To guarantee your ice cream machine stays in top shape, follow these steps:

- Use a clean towel or air dry all removable parts, paying special attention to crevices and joints.

- Store small parts in airtight storage containers to keep dust and moisture out.

- Wipe down the main unit with a dry cloth, avoiding excess moisture that can lead to rust.

Check for Wear and Damage

You should carefully inspect your ice cream machine for any cracks or damage that could worsen over time. Check all moving parts to guarantee they aren’t worn or broken, which might affect performance later. Addressing these issues now can save you headaches when you’re ready to use it again. Additionally, inspecting for wear and tear can help identify potential mechanical problems before they become costly repairs. Regular maintenance and routine checks can extend the lifespan of your machine and ensure optimal operation. Incorporating preventive maintenance practices can further reduce the risk of unexpected breakdowns and ensure consistent performance. Being aware of hidden issues can also prevent sudden failures that disrupt your plans.

Inspect for Cracks

Inspecting your ice cream machine for cracks is a crucial step before storing it for the off-season. Crack detection helps guarantee the machine’s structural integrity remains intact and prevents future issues. To do this effectively:

- Visually examine all surfaces, focusing on joints and corners where cracks often start.

- Run your fingers gently along seams and panels to feel for any roughness or splits.

- Use a flashlight to highlight fine cracks that might be hard to see in normal light.

- Remember that machine durability can be affected by unnoticed cracks, so thorough inspection is essential.

- Incorporating preventative maintenance practices can help identify potential problems early and extend the lifespan of your equipment.

- Regular inspections and proper storage conditions are vital to avoid damage from environmental factors, ensuring your machine stays in good condition during the off-season.

- Additionally, considering heat and humidity control during storage can help prevent material expansion or contraction that may lead to cracking. Proper environment management reduces the risk of material deterioration and keeps your machine in optimal condition.

- Address any visible cracks immediately, as they can worsen over time and compromise the machine’s durability. Making certain there are no cracks helps maintain the structural integrity of your equipment, making it safer and more reliable when you resume use.

Examine Moving Parts

Examine the moving parts of your ice cream machine carefully for signs of wear or damage, as these can affect performance and longevity. Check belts, gears, and paddles for cracks, chips, or looseness. Look for any unusual noises or resistance during operation. Proper moving part lubrication is essential to keep everything running smoothly; use appropriate lubrication techniques to prevent rust and reduce friction. Apply lubrication sparingly to gears and bearings, avoiding excess that could attract dust or debris. Regularly inspecting and maintaining these parts ensures smooth operation and prevents breakdowns during the season. If you notice any damage or excessive wear, replace or repair parts before storing the machine. Proper maintenance now helps extend your machine’s lifespan and ensures it’s ready to use when the season begins again.

Lubricate Moving Components if Necessary

If your ice cream machine has moving parts like gears or chutes, lubricating them can help prevent rust and guarantee smooth operation when you restart it. Proper maintenance involves these key steps:

- Identify all moving components that need lubrication.

- Clean each part thoroughly to remove old grease, dirt, or debris.

- Apply a suitable grease to lubricate components, ensuring even coverage.

Be sure to use food-grade lubricants to avoid contamination. If necessary, gently apply grease to gears, chutes, or other moving parts to keep everything functioning smoothly. This step can prevent squeaking, reduce wear, and extend your machine’s lifespan. Regular lubrication is essential during off-season storage, so don’t skip it! Properly lubricated components will make your reassembly quicker and easier when you’re ready to use your ice cream machine again.

Store in a Clean, Dry Location

After lubricating the moving parts, it’s important to store your ice cream machine in a clean, dry location. A proper cleaning process ensures no residue or food particles attract mold or pests during storage. Wipe down all surfaces thoroughly, paying attention to hard-to-reach areas. Choose a storage location that stays dry and cool, away from humidity and temperature fluctuations, which can cause rust or damage. Avoid storing it in damp basements or garages prone to moisture. Keeping the machine in a clean, dry spot preserves its condition and functionality. Before storing, double-check that all parts are dry and clean to prevent mold growth. Proper storage location and cleanliness are key to maintaining your ice cream machine’s lifespan and readiness for next season.

Protect With Cover or Plastic Wrap

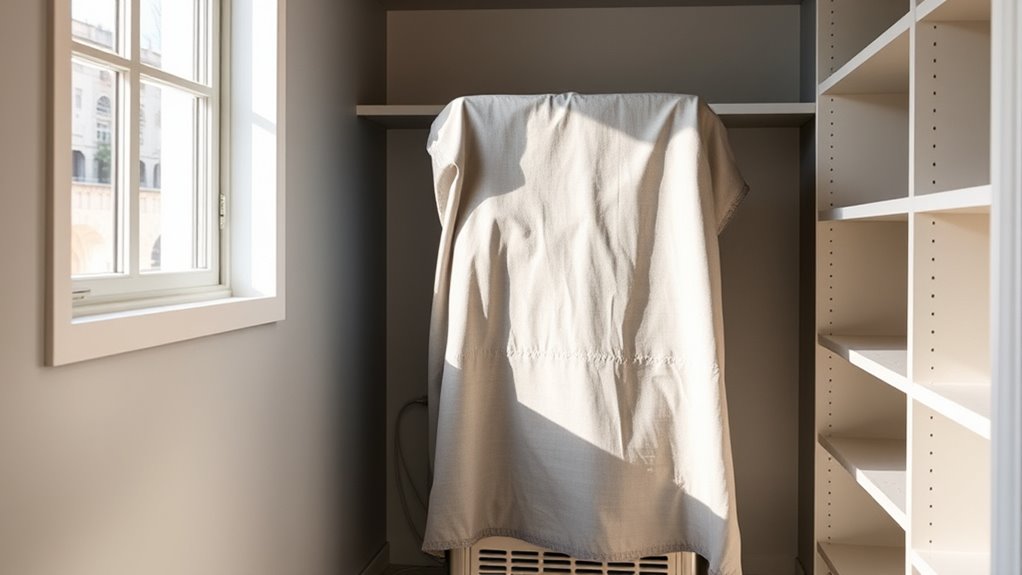

Cover your ice cream machine with a breathable cover or plastic wrap to keep dust off. This simple step also helps safeguard it from moisture that could cause damage. Taking these precautions ensures your machine stays clean and in good shape for next season.

Prevent Dust Accumulation

Dust can quickly settle on your ice cream machine during the off-season, which may lead to clogs or affect its performance when you’re ready to use it again. To prevent dust buildup, you should protect your machine effectively. First, always cover it with a breathable cover designed for appliances, which helps block dust while allowing air filtration. Second, consider wrapping it in plastic wrap or a plastic bag for an extra layer of protection against dust and debris. Third, store it in a clean, dust-free area to minimize airborne particles settling on the surface. These simple steps ensure dust doesn’t accumulate, keeping your machine clean and ready to operate smoothly when the season calls for ice cream. Proper protection helps maintain ideal performance and prolongs your machine’s lifespan.

Shield From Moisture

Moisture can cause rust and mold to develop on your ice cream machine during the off-season, potentially damaging its internal components. To protect it, use moisture barriers like plastic covers or plastic wrap to seal out humidity. These barriers help prevent moisture from reaching sensitive parts and reduce the risk of corrosion. Additionally, placing desiccant packs inside the storage area or wrapped around the machine absorbs residual moisture, keeping the environment dry. Make certain the cover is snug but not too tight, so air can circulate and prevent condensation. Regularly check on your storage setup to make sure moisture isn’t seeping in. Taking these simple steps shields your machine from moisture damage and prolongs its lifespan until you’re ready to use it again.

Keep Away From Extreme Temperatures

Extreme temperatures can seriously damage your ice cream machine during the off-season, so it’s important to store it in a controlled environment. Temperature regulation is key—avoid areas that fluctuate between freezing and hot. Humidity control also matters; excess moisture can cause rust and mold. To protect your machine, ensure you:

Properly store your ice cream machine in a cool, stable, and humidity-controlled environment to prevent damage during off-season.

- Store it in a cool, stable environment away from direct sunlight

- Use a dehumidifier or silica gel packs to maintain proper humidity levels

- Check the storage area regularly for temperature consistency

Keeping your ice cream machine in a temperature-controlled space prevents warping, electrical issues, and corrosion. By maintaining stable conditions, you’ll preserve your machine’s longevity and ensure it’s ready to go when the season starts again.

Maintain Proper Air Circulation

Maintaining proper air circulation around your ice cream machine is essential to prevent overheating and moisture buildup during storage. Adequate airflow optimization helps keep internal components dry and functioning properly, reducing the risk of mold and corrosion. To achieve this, follow ventilation tips like placing the machine in a well-ventilated area away from walls or obstructions, ensuring air can freely circulate. Avoid stacking items around the machine, and consider using a small fan if natural airflow is insufficient. Regularly check that vents are clear of dust and debris. Proper ventilation not only extends the lifespan of your machine but also keeps it in top condition for when you’re ready to use it again. Prioritize airflow to ensure your ice cream machine stays safe during the off-season.

Test and Prepare Before Next Use

Before you store your ice cream machine for the off-season, it’s important to test and prepare it for its next use. Proper seasonal maintenance guarantees your machine stays in top shape and storage safety is maintained. Start by:

- Running a cleaning cycle to remove any residual product and prevent mold.

- Checking all parts, like blades and seals, for wear or damage, replacing if necessary.

- Ensuring the machine is completely dry to prevent rust and mold during storage.

This process helps identify issues early and keeps your machine ready for quick setup. Testing and preparing your ice cream machine now reduces the risk of problems later and ensures safe storage. Proper preparation preserves the machine’s lifespan and guarantees delicious treats when you’re ready to use it again.

Follow Manufacturer’s Storage Recommendations

Following your ice cream machine’s manufacturer’s storage recommendations is crucial to guarantee it remains in good condition during the off-season. Always refer to the manufacturer guidelines to ensure proper storage procedures. These guidelines specify the ideal storage environment, including temperature, humidity, and ventilation requirements, which help prevent damage or deterioration. Ignoring these instructions can lead to issues like mold growth, component corrosion, or mechanical problems later on. Before storing, clean and dry your machine thoroughly to follow the recommended procedures. Store it in a cool, dry, and well-ventilated area—avoiding extreme temperatures or direct sunlight. By adhering to the manufacturer’s guidelines and choosing the right storage environment, you’ll protect your investment and ensure your ice cream machine is ready for use when the season returns.

Frequently Asked Questions

How Long Can I Store My Ice Cream Machine Off-Season?

You can store your ice cream machine off-season for several months if you follow proper storage tips. First, clean the machine thoroughly using recommended cleaning procedures to prevent mold and residue buildup. Make sure to dry all parts completely before storing. Store it in a cool, dry place, and cover it to protect from dust. Proper storage guarantees your machine stays in good condition and ready to use when the season returns.

Can I Store the Machine Outdoors During Off-Season?

You might think outdoor storage is a piece of cake, but it’s really a wolf in sheep’s clothing. Storing your ice cream machine outdoors during the off-season isn’t advisable because it exposes the machine to weather, moisture, and temperature swings. To protect your investment, find a sheltered spot with weather protection, like a shed or garage. Keep it dry and covered, and you’ll avoid unnecessary damage and costly repairs.

Should I Disconnect the Power Before Cleaning?

Yes, you should disconnect the power before cleaning your ice cream machine to guarantee power safety. This prevents accidental activation and potential injuries. Regular cleaning frequency keeps your machine in top condition and prevents buildup. Always unplug the machine first, then carefully clean all removable parts and surfaces. This simple step protects you and prolongs your equipment’s lifespan, making maintenance safer and more effective.

Is It Necessary to Drain All Liquids Before Storage?

If you don’t drain all liquids, mold could grow faster than a summer heatwave! You must remove all liquids from your ice cream machine to prevent mold and bacteria from thriving during storage. Liquid removal is essential; it stops moisture buildup that can ruin your machine. Skipping this step risks a mold invasion, making cleaning harder later. Do yourself a favor—drain everything and keep your machine fresh and ready for next season!

How Often Should I Check on Stored Machines During Off-Season?

You should check on your stored machines at least once a month to make certain proper machine maintenance. Regular inspections help you spot any issues like leaks or mold early, keeping your equipment in top shape. Follow storage tips like keeping the machine in a cool, dry place and covering it properly. This proactive approach prevents damage, extends the lifespan, and makes reusing your ice cream machine hassle-free when the season begins again.

Conclusion

By following these steps, you’re turning your ice cream machine into a well-rested giant, ready to dazzle again after its hibernation. Imagine it tucked away like a sleeping bear in a cozy den, waiting patiently for your next sweet adventure. When spring arrives, give it a gentle wake-up call, and watch it spring back to life, enthusiastic to churn out creamy delights. Proper storage keeps your machine happy, healthy, and always ready for your next frozen masterpiece.