If your ice cream machine isn’t working well, start by cleaning and inspecting the freezer bowl, ensuring it’s fully frozen and free of residue. Double-check that all parts are properly assembled and securely locked. Examine the power cord and electrical connections for damage. Address any leaks by replacing worn gaskets or tightening fittings, and adjust the timer for the perfect texture. Keep up with regular maintenance to prevent future issues—continue for more helpful tips.

Key Takeaways

- Regularly clean and maintain the freezer bowl, ensuring it is fully frozen before use to prevent texture issues.

- Confirm all machine parts are properly assembled and securely locked to avoid leaks and operational errors.

- Inspect and replace worn gaskets and seals to prevent leaks and moisture problems during operation.

- Adjust and calibrate the freezing timer and thermostat for optimal ice cream consistency and texture.

- Check electrical connections and cords regularly for safety and proper functioning to prevent malfunctions.

Checking and Cleaning the Freezer Bowl

To guarantee your ice cream machine functions properly, start by checking and cleaning the freezer bowl regularly. A dirty or improperly frozen bowl can lead to issues with your frozen mixture, causing inconsistent textures or difficulty churning. Confirm the bowl is thoroughly clean and free of residue that can interfere with freezing. Before use, verify the bowl has frozen for the recommended time, usually 24 hours, to prevent consistency issues. If the mixture isn’t freezing evenly or remains too soft, it might be due to a partially thawed bowl or leftover buildup. Regular cleaning and proper freezing times help maintain peak performance, ensuring your frozen mixture achieves the smooth, creamy consistency you want. Proper maintenance now prevents larger problems later. Additionally, ensuring the celebrity lifestyle insights of your kitchen appliances can help you stay informed about the latest innovations for easier maintenance.

Maintaining correct temperature settings is also crucial for optimal freezing and performance.

Ensuring Proper Assembly and Locking of Parts

After cleaning and freezing the freezer bowl, make sure all parts are assembled correctly and securely locked in place. Improper assembly can cause the machine to malfunction or produce inconsistent ice cream. Double-check that the paddle is firmly attached and that the lid is securely locked, ensuring it doesn’t move during operation. When making recipe modifications or ingredient substitutions, verify that the chute and lid are properly aligned to prevent leaks or errors. Proper locking prevents air from entering, which can hinder freezing. If you notice parts aren’t fitting snugly, reassemble them carefully. Taking these steps helps your machine work efficiently and reduces troubleshooting time. A secure setup ensures consistent texture, especially when customizing recipes or switching ingredients. Additionally, ensuring the use of innovative materials can improve the durability and performance of your ice cream machine. Maintaining tight connections also minimizes vibrations that could affect the performance and longevity of the appliance, especially when considering refrigerants and their impact on efficiency and environmental safety.

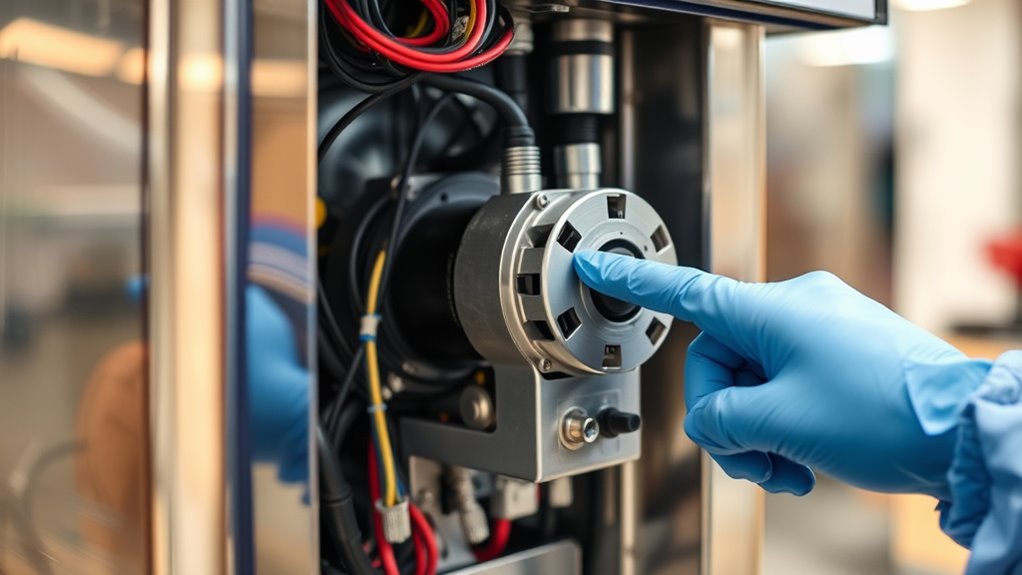

Inspecting the Power Supply and Electrical Connections

Have you checked whether your ice cream machine is receiving power properly? If not, start by inspecting the power cord and electrical connections. According to manufacturer guidelines, ensuring proper electrical safety is essential to prevent hazards or damage. You are trained on data up to October 2023. Electrical safety precautions are vital when working with household appliances to avoid potential risks. Proper inspection of electrical connections can also prevent performance issues caused by performance tuning problems or contaminants affecting the power supply. Regularly verifying the integrity of electrical components can help identify wear and tear that might affect operation. Additionally, checking for brand credibility can ensure you’re using genuine parts and authorized repair procedures. Remote work increases flexibility and can contribute to better work-life balance, which is essential in maintaining overall well-being even when troubleshooting household appliances.

Fixing Leaks and Preventing Spills

Leaks and spills can disrupt your ice cream machine’s performance and create a mess, so addressing them promptly is essential. Start by inspecting the seals and gaskets around the ice cream storage area; worn or damaged parts often cause leaks. Check for loose fittings or cracks in the hopper and dispense mechanisms, tightening or replacing as needed. To prevent spills during flavor customization, ensure the machine’s lid fits securely and that all connections are tight. Regularly clean the drip tray and surrounding areas to avoid buildup that could lead to overflow. Proper maintenance of these parts helps keep your machine tidy, preserves the quality of stored ice cream, and guarantees smooth flavor customization without messy spills. Incorporating routine maintenance can also help identify potential issues early and keep your machine functioning optimally. Additionally, monitoring machine components regularly can prevent unexpected failures and maintain optimal performance. Staying vigilant about equipment upkeep ensures longevity and consistent results. Performing regular filter replacement checks can help prevent clogs that might cause leaks or spills and keep the internal parts functioning smoothly. Using preventive measures like inspecting hoses and fittings periodically can further reduce the risk of leaks developing over time.

Adjusting the Freezing Timer and Settings

To guarantee your ice cream reaches the perfect consistency, it’s important to properly adjust the freezing timer and settings. Start by checking the temperature calibration to ensure your machine’s thermostat is accurate. Next, fine-tune the timer adjustment to prevent overfreezing or underfreezing. Here are some tips:

Ensure perfect ice cream consistency by calibrating the thermostat and fine-tuning the freezing timer.

- Set the timer based on your desired ice cream texture

- Adjust temperature calibration for consistent results

- Test run and monitor the consistency during initial batches

- Use a thermometer to verify the actual temperature matches the setting

- Make small adjustments to avoid drastic changes in texture

- Ensure the headphone jack is properly connected if your machine relies on audio cues for operation or troubleshooting.

- Regularly inspect and maintain the compressor to ensure optimal cooling performance.

- For optimal operation, understanding the cooling system can help you diagnose potential issues early.

- Regularly cleaning and replacing filters can ensure the air quality around your appliance remains optimal, preventing overheating.

- Staying informed about machine learning algorithms can also help in understanding how advanced control systems optimize appliance performance.

Troubleshooting Noisy or Unusual Sounds

If your ice cream machine starts making loud or unusual noises, it can signal a mechanical issue or a need for maintenance. Motor noise often indicates that the motor is working harder than it should, possibly due to debris or worn components. Vibration issues might suggest loose parts or misalignment within the machine. First, unplug the machine and check for any obstructions or debris around the motor and moving parts. Tighten loose screws or bolts that could be causing excess vibration. If the noise persists, inspect the motor for signs of wear or damage. Sometimes, lubricating moving parts can reduce noise and vibration. Regular maintenance helps prevent these issues from worsening, keeping your ice cream machine running smoothly and quietly. Additionally, consulting an expert or service professional can help diagnose more complex problems. Being aware of mechanical issues can help you identify problems early before they lead to more costly repairs.

Replacing or Repairing Faulty Gaskets and Seals

Faulty gaskets and seals can cause moisture issues and compromise the performance of your ice cream machine. Over time, gasket material can degrade, leading to leaks or contamination. To fix this, inspect your gaskets and consider seal replacement if you notice cracks, brittleness, or gaps. When replacing gaskets, choose the right material—rubber, silicone, or neoprene—to match your machine’s specifications. Proper installation ensures a tight seal, preventing moisture intrusion and maintaining ideal pressure. Here’s what to do:

- Turn off and unplug your machine before working on it

- Remove old gaskets carefully, noting their placement

- Clean sealing surfaces thoroughly

- Select high-quality gasket material compatible with your machine

- Install new gaskets securely, ensuring no gaps exist

Replacing faulty gaskets and seals restores your machine’s efficiency and prevents future issues.

Maintaining Your Ice Cream Maker for Optimal Performance

Regular maintenance is key to keeping your ice cream maker running at peak performance. To ensure consistent ice cream quality and flavor enhancement, regularly clean all parts, including the churning bowl and blades. Keep the machine dry and inspect seals and gaskets for wear, replacing them if needed. Properly lubricate moving parts to prevent stiffness or malfunction. Always follow manufacturer instructions for cleaning and storage. Freezing the bowl thoroughly before use helps achieve the right texture and reduces overworking the motor. Additionally, maintaining a clean machine prevents buildup that can affect the flavor and texture of your ice cream. By staying on top of these simple maintenance steps, you’ll enjoy smoother operation, better flavor, and longer-lasting equipment.

Frequently Asked Questions

How Often Should I Perform Maintenance on My Ice Cream Machine?

You should perform maintenance on your ice cream machine regularly to guarantee peak performance. Typically, you need to do a thorough machine cleaning after every 24 to 48 hours of use, especially if used frequently. Additionally, inspect and replace parts as needed—such as seals or blades—every few months. Regular maintenance helps prevent malfunctions, extends your machine’s lifespan, and keeps your ice cream tasting fresh and delicious.

Can I Use My Ice Cream Maker Outdoors Safely?

Think of your ice cream maker as a delicate flower—it needs proper care to thrive. You can use it outdoors, but only if you consider weather conditions and outdoor safety. Avoid exposing it to rain, direct sunlight, or extreme temperatures. Always guarantee it’s on a stable surface and protected from moisture. When in doubt, bring it inside after use to prevent damage and keep your machine in top shape.

What Ingredients Are Best Suited for My Ice Cream Machine?

When choosing ingredients for your ice cream machine, focus on ingredient compatibility to guarantee smooth operation and prevent damage. Use fresh dairy, sugar, and flavorings that blend well and don’t clog the machine. For flavor customization, experiment with fruits, nuts, or extracts, but keep the mix balanced for ideal texture. Always follow your machine’s guidelines to get the best results and create delicious, personalized ice cream every time.

How Do I Store My Ice Cream Maker During Off-Season?

Like a well-kept knight’s armor, your ice cream maker needs proper seasonal storage. First, clean your machine thoroughly, following cleaning tips to prevent mold and residue. Then, dry all parts completely to avoid rust. Store it in a cool, dry place, ideally in its original box or a protective cover. This keeps your machine ready for next summer’s sweet adventures, just like a trusty steed waiting for the next ride.

Is It Normal for My Machine to Make Noise During Operation?

You might notice some noise during your ice cream machine’s operation, which is normal. Expect slight motor noise and some machine vibration as the compressor runs and the paddles churn. However, if the noise becomes unusually loud or persists, it could indicate a problem. Regular maintenance can help minimize excess vibrations and guarantee smooth operation. Keep an eye on the sounds to catch issues early and keep your machine running efficiently.

Conclusion

Think of your ice cream machine as a loyal steed. When it’s well-maintained and cared for, it gallops smoothly, ready to serve up sweet moments. But neglect its needs, and it stumbles. By following these simple steps, you’re guiding your trusty machine back to its peak performance. Keep it clean, checked, and attended, and it’ll reward you with endless delightful treats—your faithful partner in frozen fun.