Choosing between air-cooled and water-cooled machines depends on your needs for performance, noise, space, and maintenance. Air cooling is simpler, more compact, and easier to maintain, making it ideal for smaller setups. Water cooling offers superior heat management, quieter operation, and better stability during intense tasks but requires more space and upkeep. To find the best fit for your situation, explore the detailed differences and benefits that follow.

Key Takeaways

- Water cooling offers superior thermal performance, higher overclocking potential, and quieter operation compared to air cooling.

- Air cooling is simpler, more compact, and easier to maintain, ideal for limited space and low maintenance setups.

- Water cooling involves higher initial costs and maintenance but provides better long-term efficiency and stability.

- Air cooling is generally safer with fewer leak risks, making it suitable for users prioritizing simplicity and safety.

- Choose water cooling for high-performance, demanding applications; opt for air cooling for basic, space-constrained, or budget-conscious needs.

Understanding the Fundamentals of Air Cooling

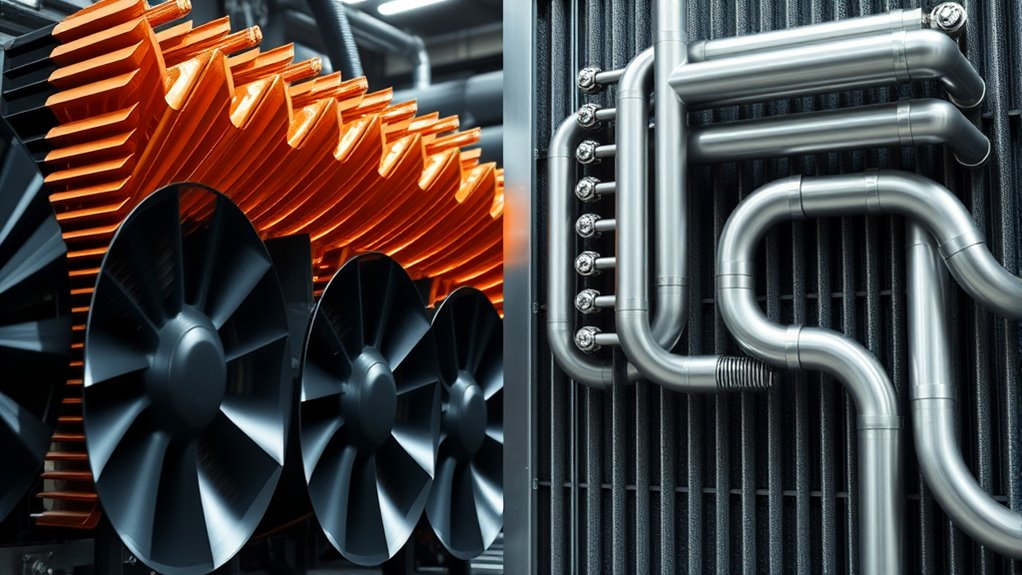

Understanding the fundamentals of air cooling begins with recognizing how it uses fans and heat sinks to dissipate heat from a machine’s components. Fans generate airflow that moves cool air over heat sinks, which absorb and spread heat away from critical parts like the CPU or GPU. Proper airflow dynamics are essential; when airflow is efficient, heat exits quickly, keeping temperatures stable. Additionally, choosing the right fan configuration can significantly impact cooling performance and noise levels. However, increased cooling noise can occur if fans run at higher speeds to improve airflow. Balancing noise levels with effective cooling is key to a quiet, well-functioning system. By understanding how fans, heat sinks, and airflow work together, you can optimize your air-cooled setup for better performance and reduced noise, ensuring your machine stays cool without unnecessary disturbance. Understanding airflow management is crucial for maximizing cooling efficiency and maintaining optimal device temperatures. Moreover, selecting the appropriate fan type and placement can further enhance cooling effectiveness while minimizing noise. Proper component placement within the case also plays a vital role in creating an optimal airflow path and preventing hotspots.

Exploring Water Cooling Technologies

Water cooling technologies come in various types, each offering unique benefits for efficient heat management. You’ll find that they often outperform air cooling regarding cooling capacity and stability. However, it’s important to take into account the maintenance requirements and costs associated with these systems to determine if they’re the right fit for your setup. Additionally, understanding potential issues such as corrosion and leaks is crucial for maintaining system longevity. Regular inspections and using corrosion-resistant materials can help mitigate these problems and extend the lifespan of your cooling system. Being aware of odor detection can also help identify early signs of issues like bacterial growth or contamination that may affect cooling components. Incorporating mindfulness techniques into your maintenance routine can promote a calmer approach to troubleshooting and system care, ultimately improving your system’s longevity. Considering the financial impact of high-quality water cooling systems can help justify the initial investment for long-term benefits.

Types of Water Cooling

When it comes to water cooling, several technologies stand out for their effectiveness and applications. You’ll encounter options like closed-loop systems, which are easy to install and require minimal maintenance, and custom-loop setups, offering advanced coolant types for tailored cooling performance. Immersion cooling is another innovative method, submerging components directly in a dielectric fluid for maximum heat dissipation. Each type integrates with the cooling system differently, depending on your needs and hardware setup. Closed-loop systems are ideal for straightforward cooling, while custom loops suit high-performance setups demanding precise temperature control. Understanding these types helps you choose a solution that aligns with your cooling system integration needs, ensuring efficient heat management for your machine or system. Water cooling technologies continue to evolve, providing more efficient options for various computing and hardware applications. Additionally, selecting the appropriate cooling method can significantly improve the longevity and reliability of your equipment. Proper system design ensures optimal performance and minimizes potential issues related to thermal management.

Advantages Over Air Cooling

Compared to air cooling, water cooling technologies offer several clear advantages that can considerably enhance your system’s performance. Water cooling provides superior noise reduction because it operates more quietly than fans, creating a calmer environment. Additionally, it offers enhanced aesthetic appeal, with sleek, customizable components that can elevate your setup’s look. Water cooling also enables more efficient heat dissipation, allowing for higher overclocking potential and improved stability. The table below highlights key benefits:

| Benefit | Description | Impact |

|---|---|---|

| Noise reduction | Quieter operation than air cooling | Less disturbance |

| Aesthetic appeal | Sleek, customizable design | Visual enhancement |

| Heat dissipation | More efficient cooling | Better performance |

| Overclocking potential | Supports higher speeds without overheating | Increased system power |

Furthermore, water cooling can help address thermal management challenges more effectively, ensuring your components stay within safe temperature ranges during intensive use. Its ability to maintain lower temperatures enhances overall system longevity, making it a preferred choice for high-performance setups. Additionally, water cooling systems often incorporate advanced materials that improve durability and corrosion resistance, further extending their lifespan. Water cooling clearly surpasses air cooling in these areas, making it a compelling choice.

Maintenance and Costs

Although water cooling systems offer significant performance benefits, they also require ongoing maintenance and can incur higher initial costs. You’ll need to regularly check and replace coolant, inspect pumps, and monitor for leaks, which adds to the maintenance complexity. Over time, these systems can lead to cost savings through improved efficiency and reduced energy consumption, but the upfront investment is often higher. Additionally, repairs can be more costly due to the specialized components involved. If you’re willing to manage the extra maintenance tasks, water cooling can deliver better cooling performance and potentially lower operating costs in the long run. Proper system monitoring can help you detect issues early and prevent costly failures, making maintenance more manageable. Implementing preventive maintenance routines can further extend the lifespan of your components and ensure consistent performance. Regular system audits can also help identify vulnerabilities and optimize overall system health. Furthermore, understanding the coolant management process is crucial for maintaining optimal system conditions. However, you’ll need to weigh these benefits against the increased maintenance efforts and initial expenses to decide if it’s right for your needs. Incorporating ethical hacking principles such as continuous monitoring can help you detect and address issues proactively, ensuring your water cooling system remains secure and efficient.

Performance Comparison: Efficiency and Effectiveness

When comparing air-cooled and water-cooled machines, you’ll notice differences in cooling efficiency that impact overall performance. These differences can lead to variations in power output and operational effectiveness. Additionally, maintenance needs and reliability often play a key role in choosing the right cooling method for your application. For example, water-cooled systems generally require more regular maintenance to prevent issues like corrosion and leaks, but they tend to offer superior cooling performance. Incorporating creative problem-solving can help optimize the setup and maintenance strategies for water-cooled systems, making them more reliable and efficient over time. Moreover, understanding the personal development principles behind consistent upkeep can improve long-term system performance.

Cooling Efficiency Differences

Air-cooled and water-cooled machines differ markedly in their cooling efficiency, which directly impacts their performance under various loads. Water-cooled systems typically handle higher ambient temperatures better, maintaining consistent performance even when it’s hot outside. They also tend to be quieter because fans can run at lower speeds. Conversely, air-cooled machines may struggle as ambient temperature rises, causing increased heat and noise levels. This table highlights key differences:

| Feature | Air-Cooled | Water-Cooled |

|---|---|---|

| Ambient Temperature | More sensitive, performance drops | Handles higher temps well |

| Noise Levels | Usually louder due to fans | Quieter, less fan noise |

| Cooling Efficiency | Moderate, varies with load | High, consistent under load |

| Maintenance | Easier, less complex | More involved, needs coolant |

Choose based on your environment and noise preferences.

Power Output Variations

Water-cooled machines generally deliver higher and more stable power output compared to air-cooled systems, especially under demanding conditions. This stability is due to better heat management, allowing the machine to operate at _ideal_ power efficiency without overheating. As a result, you’ll notice consistent performance even during extended use. Water cooling also tends to reduce noise levels since it relies on liquid circulation rather than fans that generate sound. This means your machine runs quietly, making it suitable for environments where noise matters. In _regard to_ power output variations, water-cooled systems maintain steady performance, whereas air-cooled units may experience fluctuations as temperatures rise. If you prioritize consistent power and lower noise, water-cooled machines are generally the better choice.

Maintenance and Reliability

While both air-cooled and water-cooled machines require regular maintenance, water-cooled systems generally offer greater reliability thanks to their superior heat management. Water cooling prevents overheating more effectively, reducing the risk of component failure. Proper corrosion prevention is essential for water-cooled systems, as exposed parts can corrode if not maintained properly, impacting reliability. Additionally, water-cooled machines tend to operate more quietly, as they produce lower noise levels compared to air-cooled units. This quieter operation can extend equipment lifespan and improve working conditions. However, water systems need more attention to prevent leaks and corrosion, making consistent maintenance vital. Overall, water-cooled machines deliver better long-term performance, but they demand diligent upkeep to maximize their reliability and efficiency.

Cost Analysis: Initial Investment and Maintenance

When comparing the costs of cooling systems, it’s important to contemplate both the initial investment and ongoing maintenance expenses. The cost comparison reveals that air-cooled machines typically require a lower upfront investment, making them more affordable initially. You’ll save on installation costs since air cooling systems are simpler and don’t need additional components like pumps or water reservoirs. However, water-cooled systems often involve higher initial costs due to their complex setup and extra equipment. Over time, maintenance costs also differ. Water-cooled machines may incur higher expenses for water treatment, pump upkeep, and leak prevention. Conversely, air-cooled systems generally need less maintenance but might require more frequent cleaning of heat exchangers. Weighing these factors helps you determine which cooling method fits your budget and long-term financial plan.

Environmental Impact and Sustainability Considerations

Choosing between air-cooled and water-cooled systems substantially impacts your environmental footprint. Air-cooled systems typically use less water, making them more sustainable in areas with limited water resources, while water-cooled systems can be more energy-efficient, reducing overall power consumption. If you prioritize renewable energy use, water-cooled machines often enable better integration with sustainable power sources, lowering your carbon footprint. However, they may require more water and cooling infrastructure, which can have environmental costs. Conversely, air-cooled systems generally have a smaller environmental impact due to lower water use and simpler maintenance. Ultimately, your choice affects not only your operational sustainability but also your contribution to environmental conservation efforts. Balancing efficiency, resource use, and ecological impact helps you make a greener decision.

Space and Installation Requirements

The space and installation requirements for air-cooled and water-cooled machines differ markedly, impacting how you plan your setup. Air-cooled systems generally have a compact design, making them suitable for limited spaces and simpler installations. You’ll need minimal additional infrastructure, as they rely on fans and external air for cooling. In contrast, water-cooled machines often require more space due to their additional components, such as cooling towers, pumps, and piping. This increases installation complexity and may demand a dedicated area for proper setup. If space is tight, an air-cooled system could be more practical. However, if you have the room and need efficient cooling, a water-cooled machine might be worth the extra effort during installation.

Durability and Longevity of Each System

Both air-cooled and water-cooled systems can offer long-lasting performance, but their durability depends on proper maintenance and operating conditions. Air-cooled systems often have better corrosion resistance since they rely on ambient air, which minimizes exposure to moisture that causes rust. Their material durability is generally high, especially if components are made from quality metals or composites. Water-cooled systems, however, can be more susceptible to corrosion if not properly treated and maintained, potentially reducing their lifespan. Regular inspections, cleaning, and using corrosion inhibitors help extend their longevity. Ultimately, the durability of either system hinges on choosing quality materials and ensuring correct operation, which safeguards against deterioration and keeps your machine running efficiently for years.

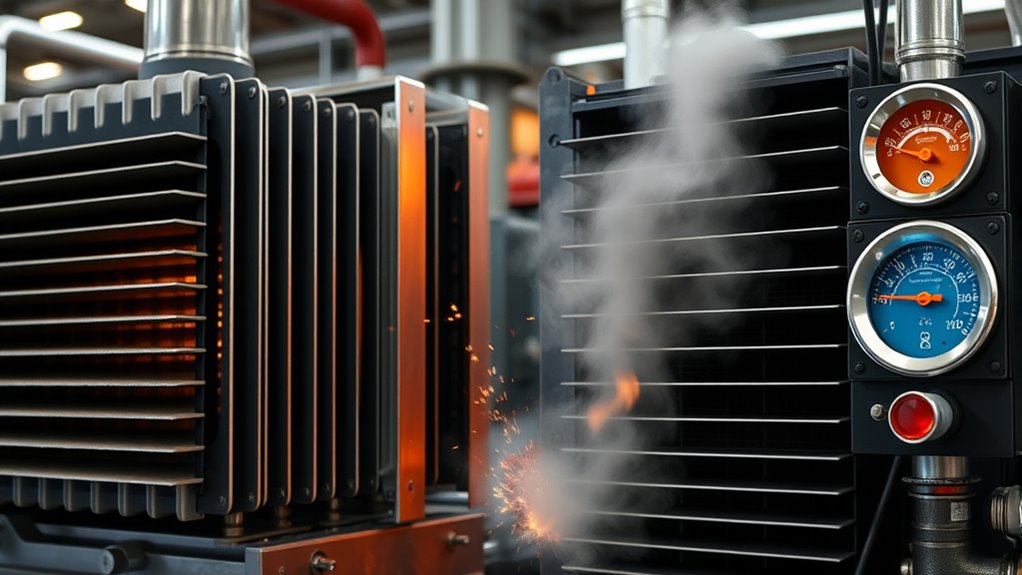

Safety and Risk Factors

While durability is important, safety and risk factors play a critical role in selecting between air-cooled and water-cooled systems. Air-cooled machines generally pose fewer fire hazards because they don’t involve liquids that can ignite or cause electrical shorts. However, they can still generate heat that may lead to overheating if not properly maintained. Water-cooled systems, on the other hand, carry risks of chemical exposure if leaks occur, especially if the coolant contains hazardous substances. Leaks can also cause electrical short circuits, increasing fire risks. Both systems require careful handling and regular inspections to minimize safety hazards. Your choice should consider these factors, ensuring you prioritize safety over convenience or efficiency, and implement proper maintenance routines to reduce potential risks.

Choosing the Right Cooling Method for Your Application

Choosing the right cooling method depends on your specific application requirements and operating environment. You need to evaluate factors like heat load, space, and maintenance. Avoid cooling system myths that suggest one method is universally better; instead, consider temperature regulation techniques suited to your needs. For example:

| Application Type | Cooling Method | Key Consideration |

|---|---|---|

| High Heat Load | Water-Cooled | Better for consistent temps |

| Compact Spaces | Air-Cooled | Easier installation |

| Continuous Use | Water-Cooled | Longer lifespan |

| Low Heat Output | Air-Cooled | Cost-effective |

| Sensitive Equipment | Water-Cooled | Precise temperature control |

Matching your application with the right cooling system ensures efficiency and longevity while debunking myths that might mislead your choice.

Frequently Asked Questions

Which Cooling System Has a Lower Noise Level During Operation?

When comparing noise levels during operation, water-cooled systems typically produce less noise than air-cooled ones. This is because water cooling reduces vibration levels and dampens sound more effectively, leading to quieter performance. If minimizing noise is your priority, you’ll find water-cooled machines offer a better noise comparison, as they generally operate more smoothly and with less vibration, making them ideal for noise-sensitive environments.

How Do Maintenance Needs Differ Between Air and Water Cooling Systems?

You’ll find that maintenance needs differ markedly between air and water cooling systems. Air-cooled units generally require more frequent maintenance, like cleaning filters and fans, due to dust buildup, but components are easier to access. Water-cooled systems need less frequent maintenance, mainly checking coolant levels and leaks, but accessing components can be more complex and time-consuming. Consider your convenience and maintenance schedule when choosing between the two.

Are There Specific Industries That Prefer One Cooling Method Over the Other?

You’ll find that industrial applications often prefer water-cooled systems because of their efficiency in handling high heat loads. Conversely, residential preferences lean toward air-cooled machines, thanks to their simpler setup and lower maintenance. Industries requiring continuous, heavy-duty cooling tend to choose water-cooled options, while smaller-scale uses favor air-cooled systems for ease and convenience. Your choice depends on your specific needs and environment.

What Are the Common Troubleshooting Issues for Each Cooling Type?

They say “prevention is better than cure,” and when troubleshooting cooling systems, addressing common issues helps. For air-cooled machines, you might face thermal inefficiencies due to blocked fans or dirty fins. Water-cooled systems often encounter corrosion issues, leading to leaks or reduced efficiency. Regular maintenance, cleaning, and checking for blockages or corrosion can keep your cooling system running smoothly and prevent costly repairs down the line.

Can Hybrid Cooling Systems Combine Advantages of Both Air and Water Cooling?

You’re wondering if hybrid cooling systems can combine the advantages of both air and water cooling. Yes, hybrid technology offers cooling integration, blending air and water cooling to optimize performance and efficiency. This setup allows you to benefit from water’s superior heat dissipation while maintaining the simplicity and reliability of air cooling. It’s an adaptable solution that helps you manage temperature effectively, especially in demanding applications.

Conclusion

Ultimately, choosing between air and water cooling depends on your specific needs. For instance, a small gaming PC might benefit from air cooling for simplicity, while a high-performance data center needs water cooling for maximum efficiency. Consider factors like space, budget, and long-term durability. By understanding these systems, you can select the right solution—ensuring peak performance and reliability for your setup. Your ideal choice keeps your machine running smoothly, just like a well-maintained server farm.